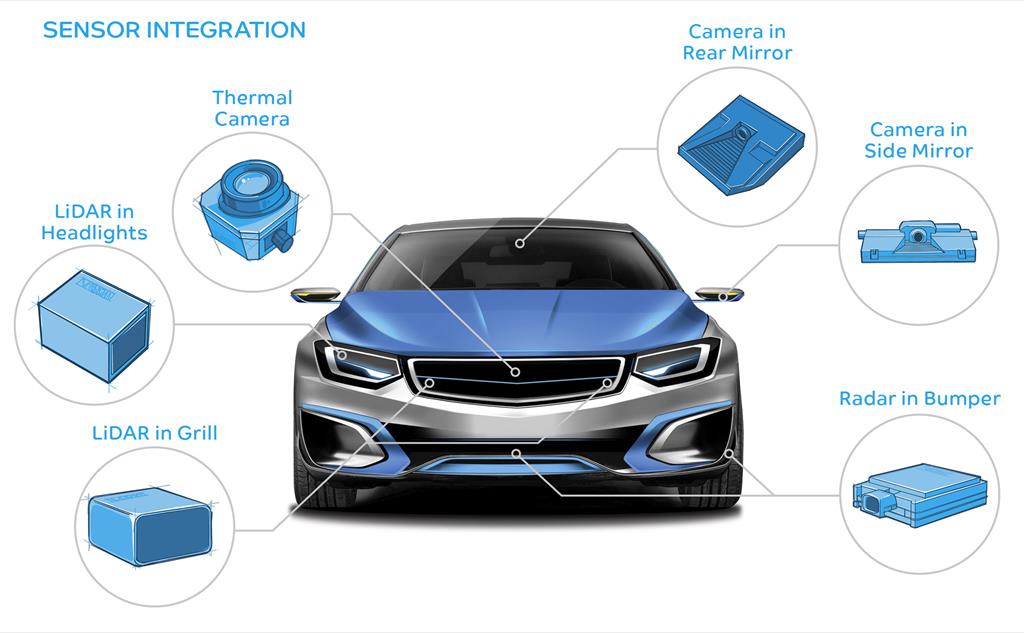

ADAS

As advanced driver assistance systems (ADAS) proliferate throughout the vehicle and become smaller, more powerful and more complex, designers require specialized materials to solve diverse challenges. These range from weight and size reduction to enhanced optical clarity, EMI shielding, and chemical and heat resistance. SABIC’s NORYL™ and ULTEM™ resins and LNP™ compounds and copolymers deliver targeted properties that address current and upcoming ADAS design needs.

For example, radar-absorbing LNP STAT-KON™ compounds shield the field of radar wave transmission and attenuate side waves that cause ghost images. LNP THERMOCOMP™ compounds offer very low dissipation factor (Df) and dielectric constant (Dk) to support transmission of higher-frequency (>75 GHz) radar signals. NORYL and NORYL GTX™ resins are well-suited for radar system covers and brackets, providing low warpage, low moisture absorption, UV resistance and laser welding capability. Optical-grade ULTEM resins offer infrared (IR) transparency for LiDAR sensors and camera lenses, helping to enable glass replacement for light-weighting.

These materials help streamline design and processing by replacing metal, avoiding painting and/or enabling part consolidation. SABIC supports ADAS customers with material selection, customization, technical support, prototyping and testing. As the ADAS market advances toward full autonomy, SABIC is driving the development of new specialized materials and capabilities.

Featured Product Brands

|

LNP™ copolymers |

Polycarbonate (PC) copolymer resins encompassing multiple product families and offering extraordinary value vs. general-purpose PC. |

|

LNP™ compounds |

Specialty compounds based on 30 different resins and incorporating different fillers and additives to achieve various effects. |

|

NORYL™ resins |

Modified polyphenylene ether (PPE) resins featuring high stiffness and strength, and good hydrolytic, chemical and creep resistance. |

|

ULTEM™ resins |

Polyetherimide (PEI) resins known for exceptional heat resistance, high strength and stiffness and broad chemical resistance. |

Radar

Radar sensors use radio waves to generate data for alerts and safety maneuvers like automatic emergency braking, adaptive cruise control and blind spot monitoring. Trends include sensor miniaturization and fusion, use of higher-frequency millimeter wave units and 4D digital radar. SABIC’s materials help to enable new designs and better resolution. Glass fiber-reinforced LNP THERMOCOMP compounds feature super-low warpage that allows for thinner radar covers for improved signal transmission, and helps sensors remain in focus to optimize visuals. High radio frequency (RF) absorption of LNP STAT-KON compounds helps increase detection range. LNP FARADEX™ compounds shield against “noise” from other ADAS sensors, and high-heat ULTEM resins enable radomes to be defrosted in bad weather.

Featured Product Brands

|

LNP THERMOCOMP™ compounds |

provide chemical resistance, rigidity and low warpage which can benefit radomes and back covers. |

|

LNP STAT-KON™ compounds |

for potential use in middle plates, absorb radio waves at 20-100 GHz to help reduce ghost images that affect sensor functionality. |

|

LNP FARADEX™ compounds |

are well-suited for back covers and help shield the unit against electro-magnetic interference (EMI) from other ADAS sensors. |

|

ULTEM™ resins |

for potential use in radomes, withstand high temperatures and harsh environments, and help refine RF transparency. |

|

NORYL™ SA resins |

are well-suited for PCBs and antennas and feature low dielectric loss. |

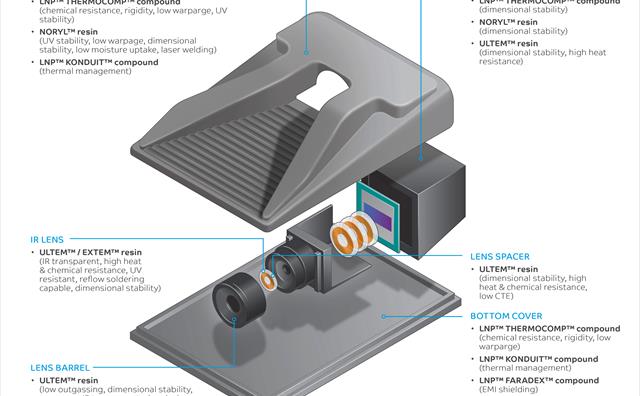

Camera

Automotive cameras are used alone and with other ADAS units to eliminate blind spots during backing and parking; monitor driver and passenger behavior; and power adaptive speed/cruise control. ADAS camera designers seek materials that can help deliver excellent image quality for accurate detection in different weather, lighting and temperature conditions. ULTEM resins are well suited for camera lens systems, including lens barrels and lens spacers, where they can provide IR transparency and resistance to high heat, chemicals and UV light. Importantly, ULTEM resins remain dimensionally stable under harsh conditions to help optimize accuracy and support consistent operation.

Featured Product Brands

|

ULTEM™ resins |

for potential use in IR lenses, barrels and spacers, provide IR transparency, weatherability, dimensional stability and low outgassing. |

|

NORYL™ resins |

are well-suited for bottom and top covers of the camera unit, and provide dimensional stability, low moisture uptake and laser welding capability. |

|

NORYL™ SA resins |

feature low dielectric loss and can be used in PCBs and antennas. |

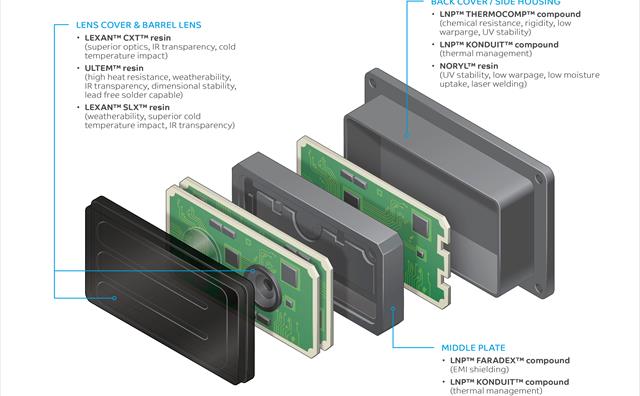

LiDAR

Because automotive LiDAR units depend on an unobstructed line-of-sight to send and receive laser light pulses, units are being embedded in headlamps and front and rear fascias. Embedding also helps maintain the vehicle’s aerodynamic design. However, this approach exposes the unit to environmental stresses that can affect useful life and performance. To protect LiDAR components from weather, temperature extremes and road debris, SABIC offers specialized materials. For the front cover and barrel lens, LEXAN SLX and LEXAN CXT copolymer resins can provide IR transparency and cold temperature impact, while high-heat ULTEM resins can supply dimensional stability and lead-free reflow soldering capability. For potential applications such as back and side covers, LNP THERMOCOMP compounds and NORYL resins provide low warpage and UV stability.

Featured Product Brands

|

LNP™ CXT resins |

(PC copolymers) provide superior optics, IR transparency and cold temperature impact. |

|

LNP™ SLX resins |

(PC copolymers) are formulated for long-term weatherability and UV resistance. |

|

ULTEM™ resins |

feature IR transparency and high heat resistance. |

|

NORYL™ resins |

are great candidates for housings that offer laser welding capability and low moisture uptake. |

|

LNP THERMOCOMP™ |

compounds provide chemical resistance, rigidity, low warpage and UV stability. |

|

LNP KONDUIT™ compounds |

can provide thermal management in middle plates and back covers. |

|

LNP FARADEX™ compounds |

deliver inherent EMI shielding, avoiding the need for plating. |

|

NORYL™ SA resins |

are well-suited for PCBs and antennas and feature low dielectric loss. |