What is BlueHero™?

BLUEHERO is SABIC’s established ecosystem of materials, technologies, expertise, and collaborative efforts – focused on accelerating the global transition to electric power and supporting progress against global goals on climate change. In addition to automotive and mobility, BLUEHERO has grown to serve a wide range of sectors – including electrical and electronics, energy storage, and supporting infrastructure. At its core, the initiative continues to drive innovation in flame-retardant materials and structural solutions that can enable safe, high-performing electric-powered applications.

Unique Materials

Cost-effective and technologically advanced flame-retardant materials that help optimize performance across electric mobility, energy storage, and electronic systems. These materials can reduce weight, enable more flexible and integrated designs, simplify system complexity, improve thermal management and fire safety, and lower environmental impact across a range of electrification applications.

Manufacturing Know-how

BLUEHERO draws on advanced processing expertise from SABIC’s MEGAMOLDING™ platform, including injection-molding, compression molding, thermoforming, and high-precision injection molding. This deep knowledge supports customers with solutions that can meet critical performance demands while enabling efficient, scalable manufacturing of large, complex thermoplastic parts.

Fire-Polymer interaction Expertise

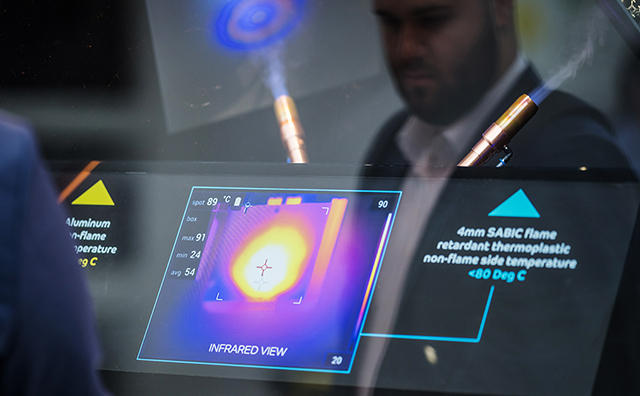

Fire safety is critical across electrified systems – from vehicles to batteries to electrical enclosures. BLUEHERO includes advanced flame-retardant polymers and deep technical expertise to help improve fire safety performance and thermal containment. Testing capabilities, both in-house and through partners, allow us to help evaluate material behavior under extreme temperature, pressure, and impact conditions, helping customers manage risk and meet safety standards.

Application Design and Verification

BLUEHERO leverages decades of experience in designing with thermoplastics to support customers in designing and validating applications requiring structural integrity, impact resistance, and thermal management. Through predictive engineering simulations, and physical testing, we help optimize part design for EVs, battery systems, E&E components, and more.

BLUEHERO™: Engineered for protection

Fire safety is a top priority as electrification technologies evolve – and at SABIC, we’re working closely with customers to help manage thermal and electrical risks with smarter material and solution choices. Our STAMAX™ 30YH570 resin is a high-flow, halogen-free flame-retardant copolymer designed for demanding applications like EV battery components. It has passed key UL fire-safety testing, reinforcing its potential to support safe, reliable electric mobility. And it’s just one of several flame-retardant solutions we offer to meet a wide range of design and safety needs.

BLUEHERO™: Enabling Electrification

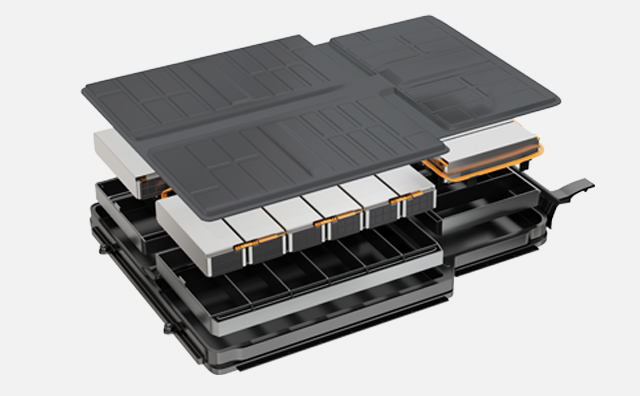

Electrified systems – whether in mobility, energy storage, or electrical infrastructure – demand new thinking and materials beyond what was used in traditional mechanical or metal-based designs. BLUEHERO supports this shift by offering specialized expertise, processing capabilities, and proven material solutions that help accelerate the development of advanced electrified applications.

Originally focused on the transition from ICE engines to EV battery systems, BLUEHERO is now playing a broader role in helping manufacturers replace legacy materials with thermoplastics that enable lightweighting, design flexibility, thermal and fire protection, and simplified assembly. These benefits extend across the electrification value chain – from battery and component manufacturers to system integrators and end users.

BLUEHERO™: Solutions

SABIC’s materials and technologies can be applied to a wide range of critical components in electrified systems – from enclosures, frames, and electrical housings to structural and protective elements in battery packs, power units, and electronic assemblies.

But BLUEHERO is more than a materials offering. It is an ecosystem that combines solutions and application expertise to help customers think beyond the individual part – optimizing total system design for improved safety, performance, and environmental impact, while keeping cost and manufacturability in mind. Whether in transportation, energy storage, or electronics, BLUEHERO is here to help power what’s next.

Featured Videos

BLUEHERO™ Knowledge Base

Repository of content on electrification materials, solutions, expertise and more.

Want to learn more or collaborate with us?

If you are exploring challenges or opportunities in electrification, we would love to hear from you. Please contact us.