RAW MATERIALS

In collaboration with suppliers, SABIC is exploring new feedstock sources that offer lower-carbon or recyclable alternatives.

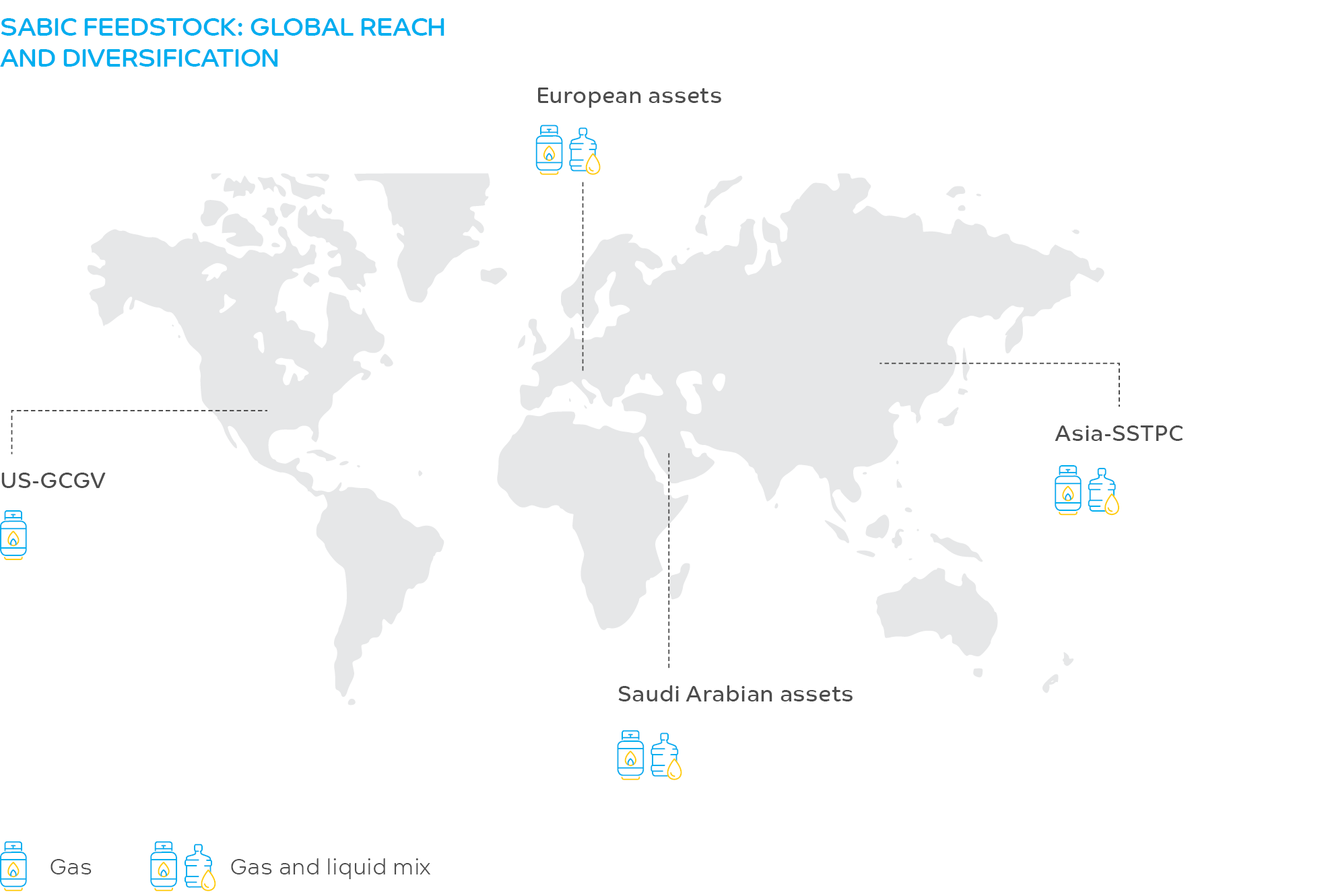

SABIC's integrated approach to raw materials seeks to maximize feedstock efficiency, reduce emissions, and enhance supply stability. SABIC relies on a range of gas and crude oil-based petrochemical products as key raw materials, including methane, ethane, propane, butane, naphtha, and condensates. Natural and liquid gas are our primary sources for energy and steam generation and serve as crucial inputs for producing essential base chemicals. Ethane, propane, butane, and naphtha are predominantly processed in our steam crackers, where they are broken down into vital feedstocks like ethylene and propylene, in addition to ammonia and methanol from natural gases processing, which form the basis of many of SABIC's value chains. This enables us to produce these chemical building blocks with greater efficiency, conserving resources and ensuring supply stability amid fluctuations.

In Saudi Arabia, SABIC benefits from long-term feedstock agreements with Saudi Aramco. Efforts are underway to ensure optimal feedstock utilization and preserve value in the event of supply interruptions. Globally, SABIC is expanding its feedstock base to ensure supply stability. In 2024, the company announced the final investment decision (FID) for the SABIC Fujian Petrochemical Complex in China. This facility will feature a mixed-feed, LPG, and naphtha steam cracker and world-class downstream units, supporting SABIC's strategy to diversify feedstock sources. Meanwhile, our joint venture with SINOPEC in China uses a balanced mix of liquid and gas feedstocks.

In Europe, SABIC's liquid crackers rely on externally sourced feedstocks, including cumene, phenol, and acetone, which serve as feedstocks for polycarbonate production at our European assets. In the U.S., operations began in 2022 at the Gulf Coast Growth Ventures ethane cracker, a joint venture with ExxonMobil.

FEEDSTOCK VALORIZATION

We aim to maximize profitability, efficiency, resilience, and sustainability by selecting and processing raw materials in the most cost-effective, reliable, safe, and sustainable manner. We produce valuable products and solutions by processing a wide range of feedstock sources both locally and globally. Our decisions consider economic, environmental, and social factors alongside critical elements such as supply security, process integrity, and product safety.

MINERAL RAW MATERIALS

SABIC also procures various mineral-based raw materials, used in applications like catalysts and battery materials for electromobility, among other products. We prioritize efforts to reduce the use of mineral-based raw materials wherever possible. Our responsible sourcing extends to transparency and compliance in the procurement of “conflict minerals”, such as tin, tantalum, tungsten, and gold.

Read more about our approach to sourcing Raw Materials , including minerals.

Disclaimer: This abridged interactive version of the SABIC Integrated Annual Report 2024 is based on the original PDF report published on this website. In case of any discrepancy, the original PDF report will prevail.