Circular Economy

We are collaborating with partners upstream and down to reinvent our way into a circular economy—and make sure used plastic never ends up in the environment, landfills, or in our oceans and instead is reused and remade into valuable new products.

SABIC TO BUILD WORLD-FIRST COMMERCIAL UNIT TO PRODUCE CERTIFIED CIRCULAR POLYMERS

SABIC partnered with Plastic Energy to build the world’s first commercial unit to produce certified circular polymers made from the upcycling of mixed and used plastics. The projects is part of our TRUCIRCLE™ portfolio.

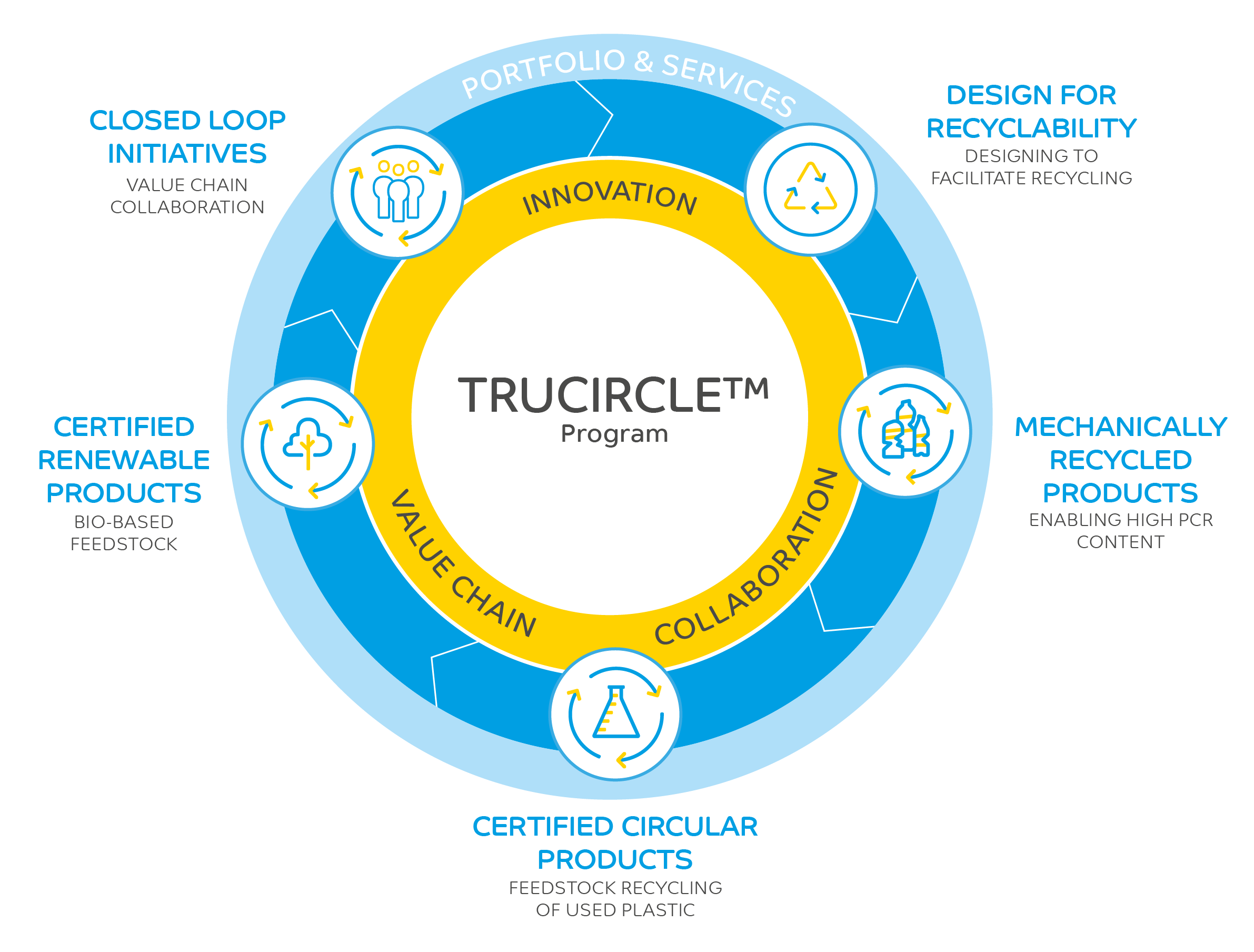

TRUCIRCLETM PORTFOLIO OF PRODUCTS AND SERVICES

In 2020, we revamped our TRUCIRCLE™ program to encompass two overarching initiatives: The initiative is built around five key principles:

- Portfolio focuses on product circularity, and we have further refined this to include three pillars: Mechanically Recycled Products, Certified Circular Products, and Certified Renewable Products.

- Services focuses on collaborations around circularity and includes two additional pillars: Design for Recyclability and Closed-Loop Initiatives.

SPOTLIGHT ON VALUE CHAIN COLLABORATION WITH TESCO