Circular Economy

In the past year, SABIC made several landmark decisions to advance the circular economy and close the loop on waste.

A Global Challenge

Plastics are vital to day-to-day life, and modern society would be impossible without them. But used plastics in waste streams pose significant challenges. SABIC is working on a vision to ensure that plastics are always reused and remade into new products.

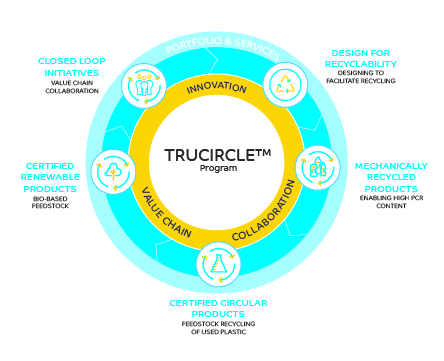

SABIC has embraced the United Nations’ Sustainable Development Goals (SDGs). This year, we unveiled our new TRUCIRCLETM initiative, which showcases our innovations to create a circular economy for plastics.

TRUCIRCLE supports SDG 12, Responsible Consumption and Production. The initiative is built around four key principles:

- Design for Recyclability

- Mechanically Recycled Products

- Certified Circular Products

- Certified Renewable Products