At MD&M West SABIC debuts biocompatible materials and Fluoropolymer alternatives, and demonstrates rapid application development

03/02/2026

SABIC, a global leader in the chemical industry, is showcasing at MD&M West 2026 medical-grade thermoplastics that help address performance, regulatory and production challenges. The company is exhibiting at Booth #3251 specialty materials well-suited for use in drug delivery, patient testing and surgery. SABIC is unveiling a new family of polycarbonate (PC) copolymers certified under UL746G, and new biocompatible SILTEM™ HU resins, which can potentially replace fluoropolymers in medical tubing. It is also illustrating its multi-prong approach to helping global customers accelerate application development through plastic design, prototyping, testing and processing services.

“SABIC goes beyond material expertise and innovation to support customer success,” said Sergi Monros, vice president, SABIC Polymers, Specialties BU. “We offer advanced technical capabilities and practical guidance at our worldwide Centers of Excellence. These resources help customers to optimize part performance, reduce costly design changes and accelerate time to market.”

SABIC addresses device industry challenges through materials innovation:

- Fluoropolymer alternatives: To help customers address per- and polyfluoroalkyl substances (PFAS) restrictions, SABIC offers materials formulated without fluorine or other PFAS chemicals. They include ULTEM™ HU resins and new SILTEM HU copolymers for use in select medical tubing applications; new LNP™ ELCRES™ NPCRX9612U resin, which is UL746G-certified as non-PFAS, for use in device housings; and internally lubricated LNP™ LUBRILOY™ compounds, formulated without PTFE, for wear/friction parts.

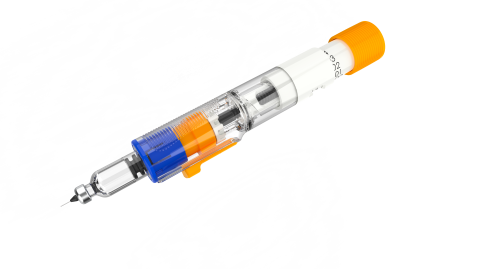

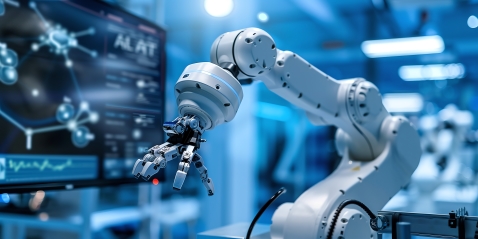

- Enhanced device performance and extended useful life. LNP ELCRES CRX copolymer resins provide best-in-class chemical resistance for equipment and device housings, while LNP SLX grades offer impact and UV resistance for applications such as the transparent cover of Rotaid’s AED cabinet. To advance surgical robot technology ULTEM HU resins deliver light-weight strength in robot wrist and arm base components. These polyetherimide (PEI) resins are compatible with popular sterilization methods. To show the scope of its medical-grade portfolio for drug delivery, the company is displaying an autoinjector demonstrator.

SABIC supports its portfolio with a Healthcare Product Policy and extensive technical resources, available at its Centers of Excellence and Global Application Technology (GApT) facilities.

MD&M West 2026 is being held at the Anaheim Convention Center in Anaheim, Calif., February 3-5.

Left: Molded from LNP™ ELCRES™ SLX resin, Rotaid’s AED cabinet cover provides impact and UV protection. (Rotaid)

Right: New non-fluorinated SILTEM HU resins can replace fluoropolymers in select medical tubing applications. (SABIC)

Left: SABIC offers a wide range of materials for drug delivery applications such as this autoinjector prototype. (SABIC)

Right: ULTEM HU resins deliver high strength and stiffness to enhance precision in surgical robots. (SABIC)