Performance and Reliability Anisotropic Modeling For Valves

CHALLENGES

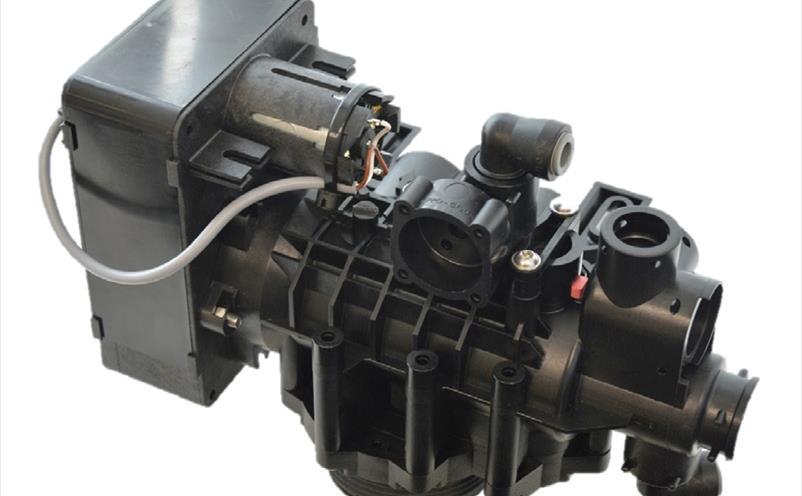

Leading water treatment technology firm BWT Wassertechnik GmbH was transitioning into NORYL FE1630PW resin on its softening valve housing. They experienced failure modes under burst and cyclic pressure testing but were unable to locate the exact failure initiation point, thereby limiting their ability to mitigate with design changes.

SOLUTION

BWT enlisted the design assistance of SABIC Predictive Engineering Services to complete advanced 3D simulations on the fiber-reinforced NORYL valve. In addition, the actual valve parts were tested at SABIC’s Water Management Center of Excellence under various loading and temperature conditions. The failure modes were visually recorded using high speed cameras and digital image correlation to determine the exact failure location

RESULTS

The combination of SABIC’s proprietary advanced NORYL™ material data with various modelling software packages enabled illustration of realistic spatial fiber orientation during mold filling. Additional simulations, which included modelling of the anisotropic performance of the glass-filled resin used in the valve, predicted two locations of part failure under specific burst and cyclic pressure conditions. The resultant insights were used to ultimately modify the part design to add a rib to relieve hoop stress in the most critical failure location. Stress at this original location was now reduced by a factor of 2.5x thereby allowing these valves to meet the BWT quality specifications for lifetime performance. SABIC Predictive Engineering Services helped to improve BWT’s confidence in their part design and decreased overall engineering design costs by accurately identifying failure modes with less iterative and physical part testing.